"S" Series Sodium Hypochlorite Generator

PARAMETERS

Chlorine Capacity: 1~50kg/h

Water treatment Capacity: 10~500 MLD

Concentration of Chlorine: 8000ppm

Salt consumption: 3.5kg/kg Cl2

Power consumption: 4kw/kg Cl2

Water treatment Capacity: 10~500 MLD

Concentration of Chlorine: 8000ppm

Salt consumption: 3.5kg/kg Cl2

Power consumption: 4kw/kg Cl2

Description

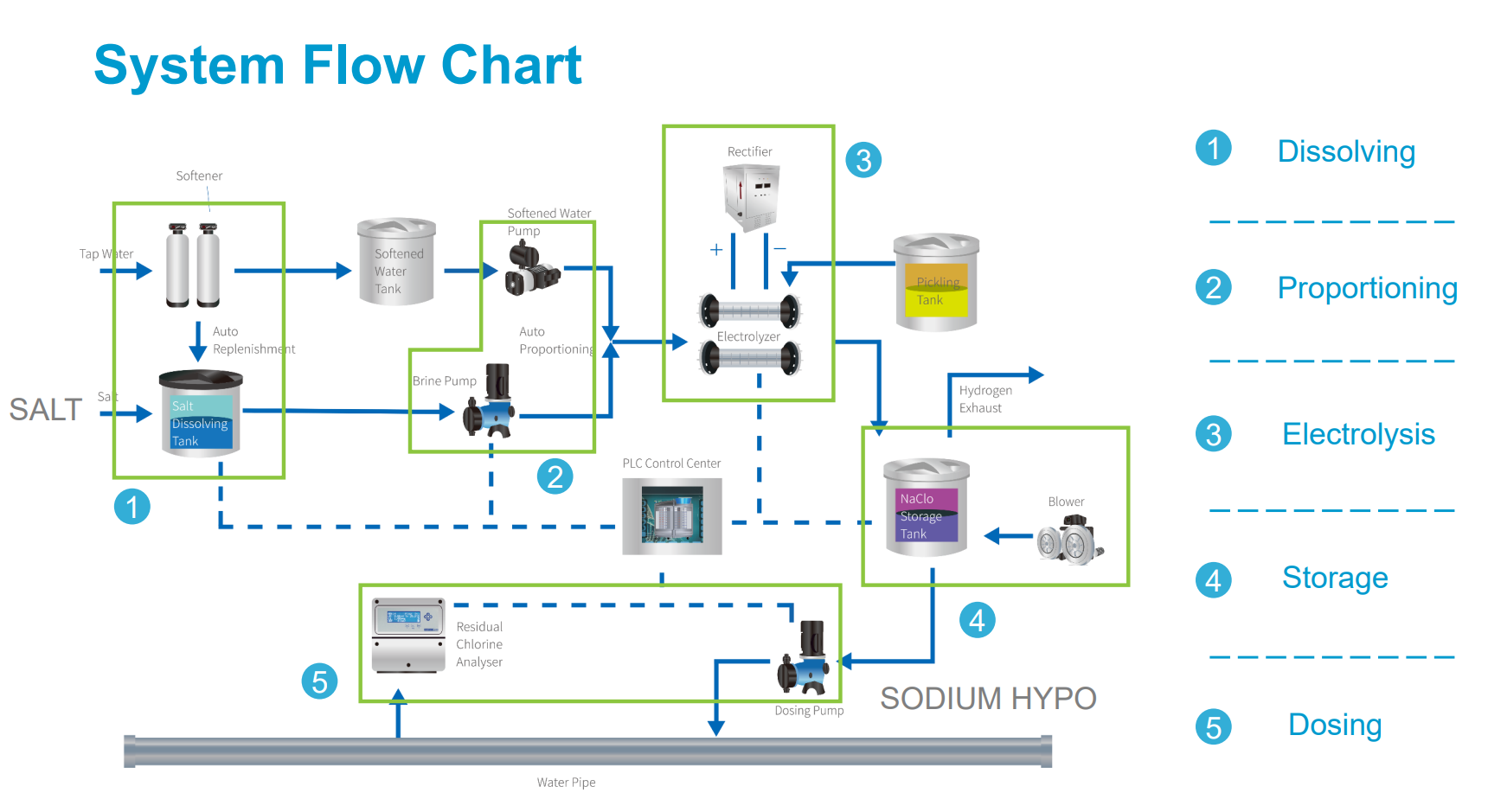

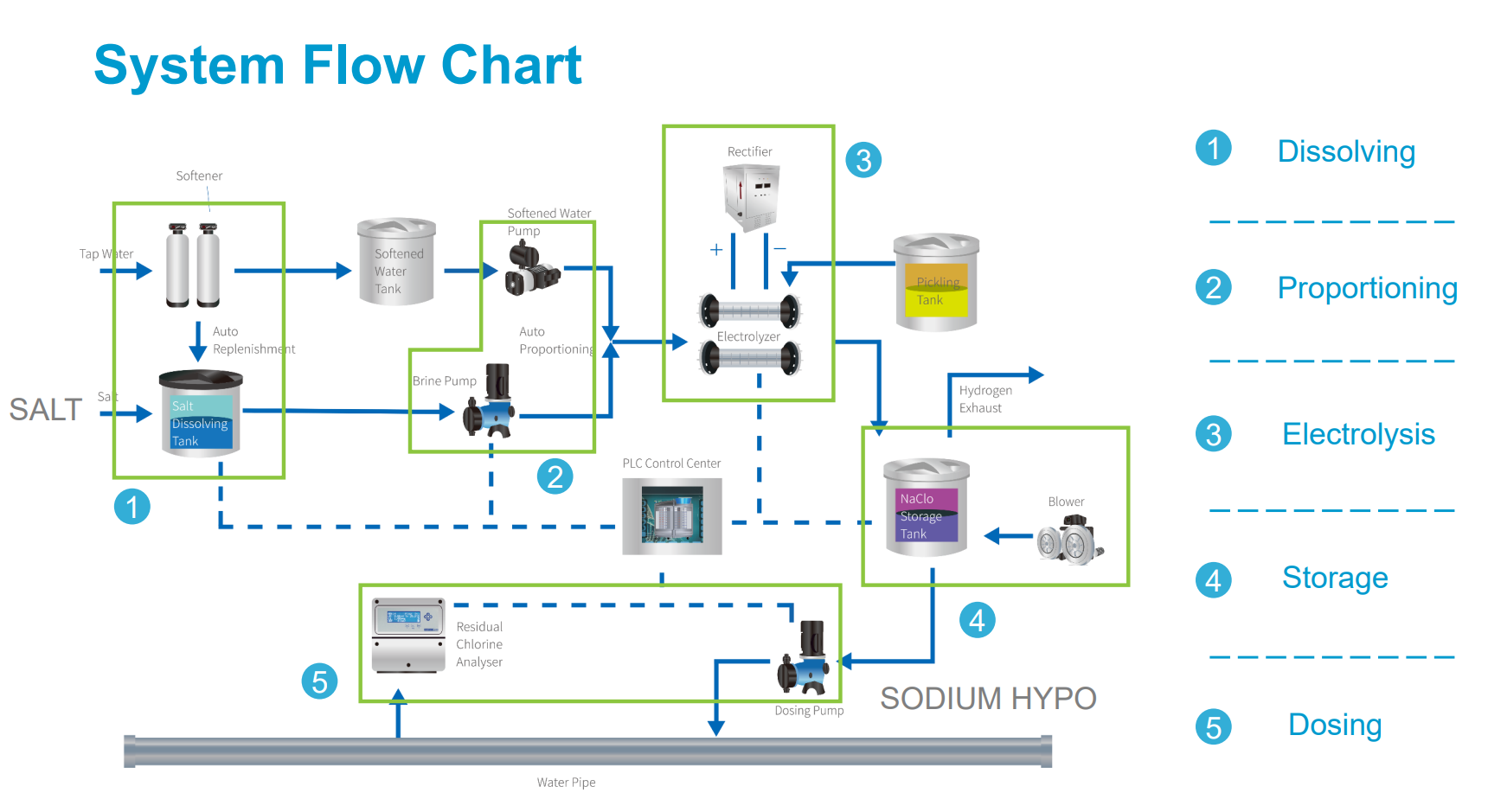

The onsite sodium hypochlorite generator use brine electrolysis to make sodium hypochlorite solution and equipped with automatic dosing device to disinfect water. The design include sodium hypochlorite production, automatic dosing and fully automatic operation. It can be included with remote monitor and control through the Ethernet and communication with host machine. The design of the system is based on energy-saving, fully automation, low operation costs, safety, stability, longevity, fault self-alarm and auto stop, etc.

① Influent water passes through a water softener to reduce hardness therefore reducing the scaling of electrodes and lengthening the cleaning time

② Salt is dissolved by softened water into saturated brine in the tank.

③ The saturated brine will be diluted into 2.5%-3%, then pass through the electrolytic cell and finally be electrolyzed into 0.8% solution of sodium hypochlorite.

④ The 0.8% hypochlorite solution flows into a storage tank. Hydrogen, the only byproduct of the process, is safely vented to the atmosphere.

⑤ Accuracy liquid dosed and controlled by residual chlorine analyser

Specifications

| GBS-1K-NACLO | GBS-5K-NACLO | GBS-10K-NACLO | GBS-20K-NACLO | GBS-50K-NACLO | |

|---|---|---|---|---|---|

| Chlorine Capacity | 1.0kg/hr | 5.0kg/hr | 10.0kg/hr | 20.0kg/hr | 50.0kg/hr |

| Water treatment Capacity(At 2ppm dosing) | 10MLD | 50MLD | 100MLD | 200MLD | 500MLD |

| Salt Consumption | 3.5kg/kg Cl2 | 3.5kg/kg Cl2 | 3.5kg/kg Cl2 | 3.5kg/kg Cl2 | 3.5kg/kg Cl2 |

| Power Consumption | 4.0kw/ kg Cl2 | 4.0kw/ kg Cl2 | 4.0kw/ kg Cl2 | 4.0kw/ kg Cl2 | 4.0kw/ kg Cl2 |

| Concentration of HYPO | 8000ppm | 8000ppm | 8000ppm | 8000ppm | 8000ppm |

| Production Flow Rate | 125 L/hr | 625 L/hr | 1250 L/hr | 2500 L/hr | 6250 L/hr |

Application

1

Municipal water & waste water plant

2

Oil & power plant

3

Food & Beverage Processing

4

Cooling Tower & Recycling

Water treatment

Water treatment

5

Aquiculture poultry farming

Advantage

Easy to get, safe and reliable.

Raw material requires salt, water, and electricity, each kg production of

chlorine, need 3.5kg salt, 105 liter water and 4kWh-AC power.

chlorine, need 3.5kg salt, 105 liter water and 4kWh-AC power.

No dangerous goods transportation.

Chlorine dioxide chemical disinfection, one of the raw material name “Hydrochloric

acid” is dangerous material, which is restricted in the purchase, storage and

transportation. Another disinfection way – chlorine gas, which is known as danger

ous disinfectant also. The on-site electrolytic sodium hypochlorite solution requires

only salt, water and electricity, no dangerous material.

acid” is dangerous material, which is restricted in the purchase, storage and

transportation. Another disinfection way – chlorine gas, which is known as danger

ous disinfectant also. The on-site electrolytic sodium hypochlorite solution requires

only salt, water and electricity, no dangerous material.

System running complete closed, no secondary leakage and pollution.

The whole process of the electrolysis to dosing is completely closed, and no need to

worry about sodium hypochlorite and hydrogen leakage, safe and reliable.

worry about sodium hypochlorite and hydrogen leakage, safe and reliable.

The on-site generation of sodium hypochlorite and dosing immediately,

instead of high strength NaClO solution which is unable to store for long

time;

instead of high strength NaClO solution which is unable to store for long

time;

Full automatic running, only salt feeding regularly

Full computer program, PLC, online chlorine analyser, ensure the residual

chlorine in water and make use of every drop of liquid

chlorine in water and make use of every drop of liquid

Central control, able to remote control, and easy control;

Easy operation, the staff can operate after simple training.