How does drinking water get to your home?

As we all know, the water is playing the vital role to our life, it is the life fountainhead, is the humanity livelihood and one of the most important physical resources of development essential. But, do you know the water sources? Most of the water come from surface water sources (e.g. rivers or lakes) or ground water sources. (e.g. wells). Water from these sources is treated at water plant to remove impurities, reducing the risk of the transmission of water borne diseases. How do the water plant treat the water?

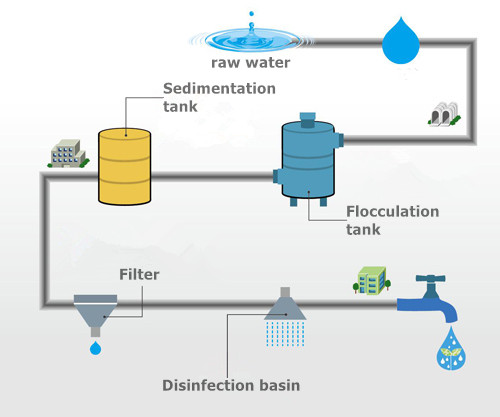

1.Raw water intake

Water is pumped into the water plant by pump from the river or lake. When the water go through the large metal grills which called screens and trash racks, the large floating objects, aquatic animals or other pollutants are separated 2.Rapid Mixing

At this stage, the chemicals Alum or Aluminum Sulphate (a coagulant), liquid polymer (a flocculant) is added to raw water, which is ensure rapid mixing and uniform distribution of the chemicals with the raw water. The Alum reacts rapidly with the water’s alkalinity to produce a gelatinous precipitate of Aluminum Hydroxide called microfloc that is injected into the tanks to remove particulate impurities from the water, such as non-settleable solids. The liquid polymer aids coagulation by enlarging the floc particles. Chlorine is added to prevent algae growth on the wall of the flocculation and sedimentation basins.

3.Flocculation

After rapid mixing, the water flows into flocculation basins, where the flow of water is slowed and the floc has time to grow bigger.

4.Sedimentation

Next, the water flows into sedimentation basins where the water moves slowly, causing the heavier solids to settle to the bottom of the tank and the lighter materials to float. The settled solids are called sludge, and is piped to drying lagoons.

5.Filtration

After leaving the sedimentation basin, the water flows through a filter designed to remove particles in the water. The filters are made of layers of sand and gravel, in order to remove dissolved particles, such as dust, parasites, bacteria, viruses, and chemicals.

6.Disinfection

After the water is filtered, then chlorination step is used for killing any remaining parasites, bacteria, and viruses, and to protect the water from germs when it is piped to homes and businesses. The sodium hypochlorite generator is a type of water treatment disinfection device which uses salt as a raw material and produce a sodium hypochlorite solution by electrolytic reaction. But, Why Choose Onsite Sodium Hypochlorite Generator? -Safety

Safe Raw Material: only salt and water required; Safe Production: the concentration of NaClO less than 1% which is classified as a non-hazardous chemical.

-Low Running Cost

To produce 1 kg available chlorine, only cost 3.5 kg of salt, 4kwh of energy.

-Onsite Generation and dosing

No chemical transportation and storage, it can be run and stopped in any time.

-Easy Operation

Full computer program and central control by PLC, the staff can operate after simple training.

7.Distribution

After chlorination, the clean water is pumped into pipes and delivered to residential area.